Took some vroom-vroom videos of The Ghost with gauges attached at various ports around the transmission. I am attempting to repair the overdrive with as little as effort as possible (the worst being having to take the transmission back out of the coach).

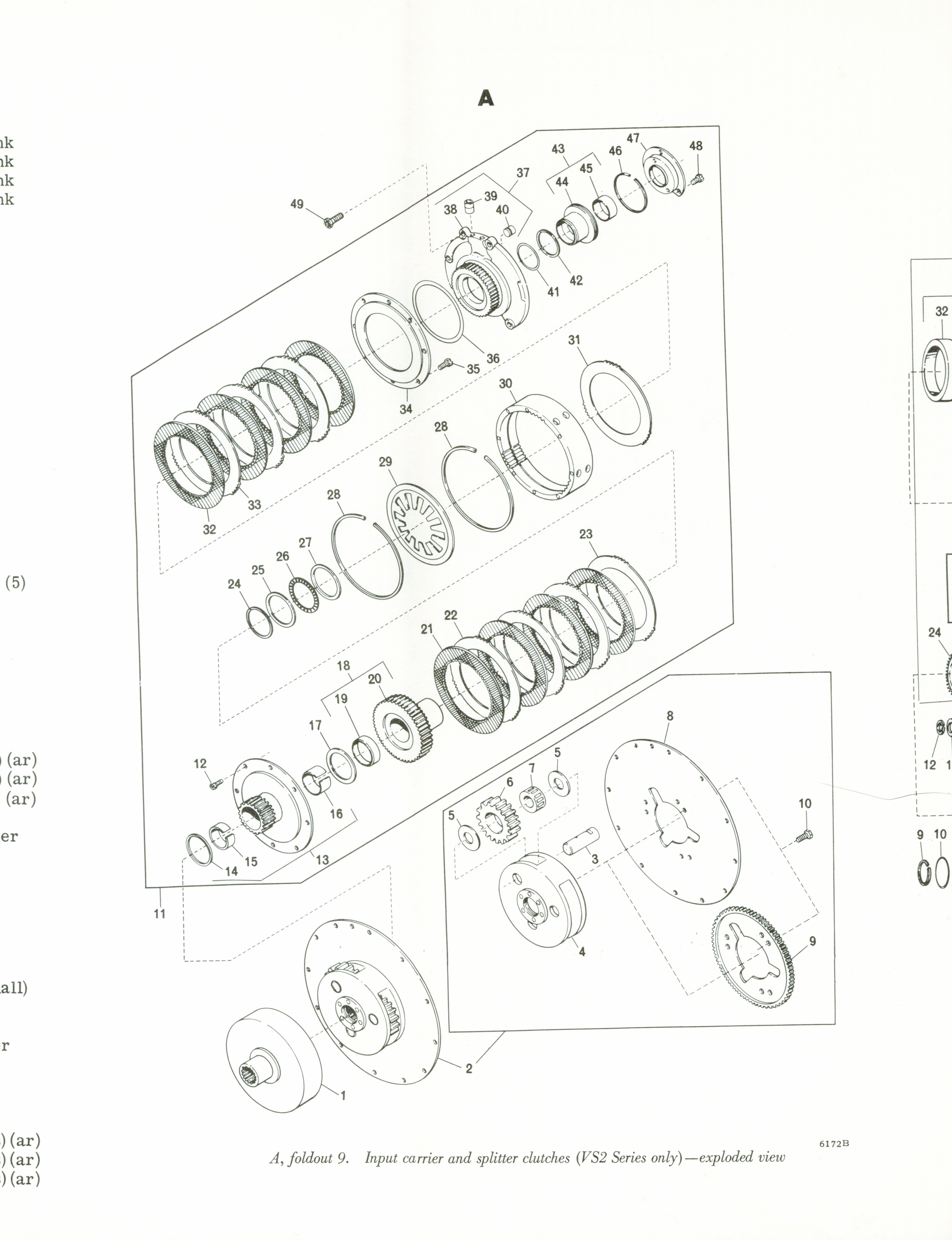

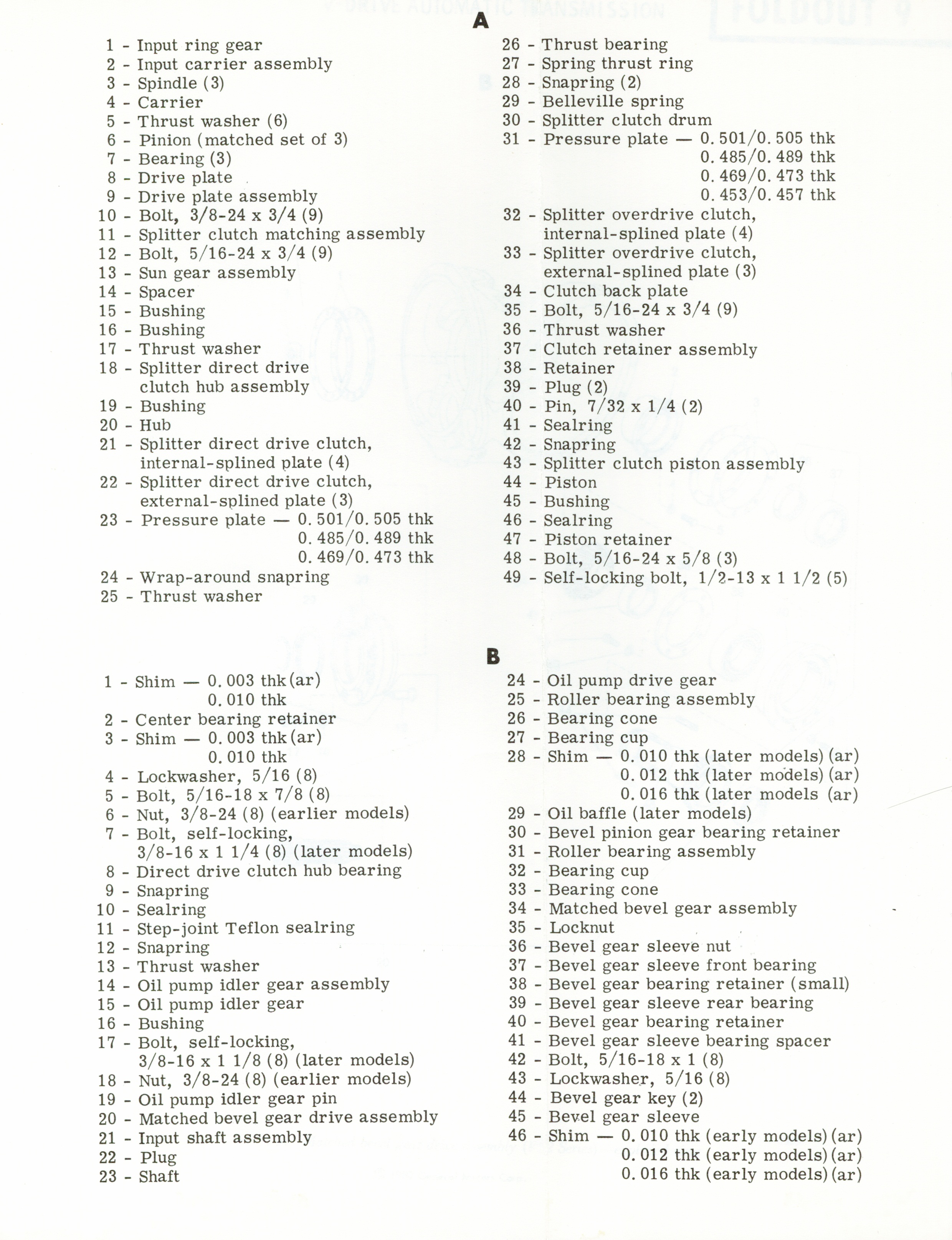

For background, The Ghost has a ‘3-speed’ automatic transmission. This transmission, an Allison VS2-8, was originally fitted to a 8V71 (the ‘8’ in the model name). I chose this transmission because unlike it’s predecessor (the Allison VH), it has an additional gear: overdrive.

The transmission starts off in ‘hydraulic’ mode (sitting at the light idling, reversing, etc.). This mode takes engine output and passes it through a VERY large torque converter (fluid coupling that multiplies torque to help get things going). Once the coach reaches a certain speed (determined by the pressure output by the governor) the transmission shifts into ‘direct drive’ by closing a clutch around the torque converter (thus taking it out of the picture). The next step, if speed and power allow, is to drop into ‘3rd gear’, where a planetary gearset drives the input of the 1:1 direct drive system over engine speed, overdrive. This allows the engine to run at a good RPM for fuel economy and torque as well as allowing the coach to travel at speeds it had never seen previously (65MPH+)

Some might ask, why all the hassle of a automatic transmission when most all automotive gurus prefer manual? The answer is simple…torque. As an example, imagine the first time you start off on a hill with a manual transmission powered car. Sometimes some clutch slipping, fair bit of engine RPM (especially if under-powered or overweight). Now multiply those issues by x10 as The Ghost is not only under-powered, it is quite heavy. There are a very limited number of manual gearboxes available for coaches of this type (V-drive, reverse rotation) and that means custom gearing can be a hassle. The torque converter action allows the bus to ‘get rolling’ by making a VERY large amount of torque without risk of stalling the engine. The downside is this generates a lot of heat, can be bad in the hills, and doesn’t give the driver a LOT of control over the shift points for climbing or descending hills. Trade offs that were considered.

The Ghost originally came with a VH transmission (hydraulic and direct drive only) which was fine for 55MPH cruising, but didn’t offer much in regards to fuel economy, comfort, or longevity. The VS2-8 was fitted in the summer of 2011 before NWMF and Burning-Man and worked like a champion. After some hassles, and finally a loud bang, overdrive disappeared and hasn’t been seen since. Since all these bits are internal to the transmission, a possible removal for diagnosis is looming.

What we see below is me testing pressures to determine if the valves, pressures, and external operation of the transmission is performing as expected. It would be pretty un-enjoyable to tear into the transmission (no small feat) only to find that the issue was something that could have been externally dealt with.

For notes, The Ghost is sitting on cribbing under both sides of the rear axle as well as resting on the chassis stands that were fitted by a previous owner. This made the coach very stable and safe to operate at 55MPH+ with the wheels a mere 1-2″ off the ground.

Enjoy.

Main Pressure Test – Youtube (pressure from which all others are derived)

Converter Pressure Test – Youtube (pressure on torque converter system)

Governor Pressure Test – Youtube (pressure that varies w/ vehicle speed to shift transmission)

Fuel Pressure Test – Youtube (fuel pressure into the fuel rail)

The summary is that Main Pressure is indicating two attempted shifts (Hydraulic to Direct, and Direct to O/D), which is good. The Converter Pressure test was mainly to give myself peace of mind that the converter pressure circuit is operating properly. The governor pressure test shows that pressure increases from 0PSI to main pressure (about 80-82psi at high speed) across it’s speed range (0-60MPH+). The Fuel Pressure test shows fuel pressure remaining stable even at high speed (although load low, so injectors not calling for a lot of fuel). I’ve had some fuel restriction issues in the past so just worth checking in. Nothing bad to write home about (both good and bad). I need to confirm one last test (a gauge connected to a service port on the O/D Valve) and if that passes, then off comes the transmission after collecting some gaskets, fluid, and spare parts.

The current thought is that either the planetary gearset for O/D just committed suicide and is locked into some strange mode of direct drive only. Another thought I have recently had is that something has happened to the spring/piston setup that activates the clutches.